3D-PRINTED CEMENT CHANNEL NETWORKS

2024

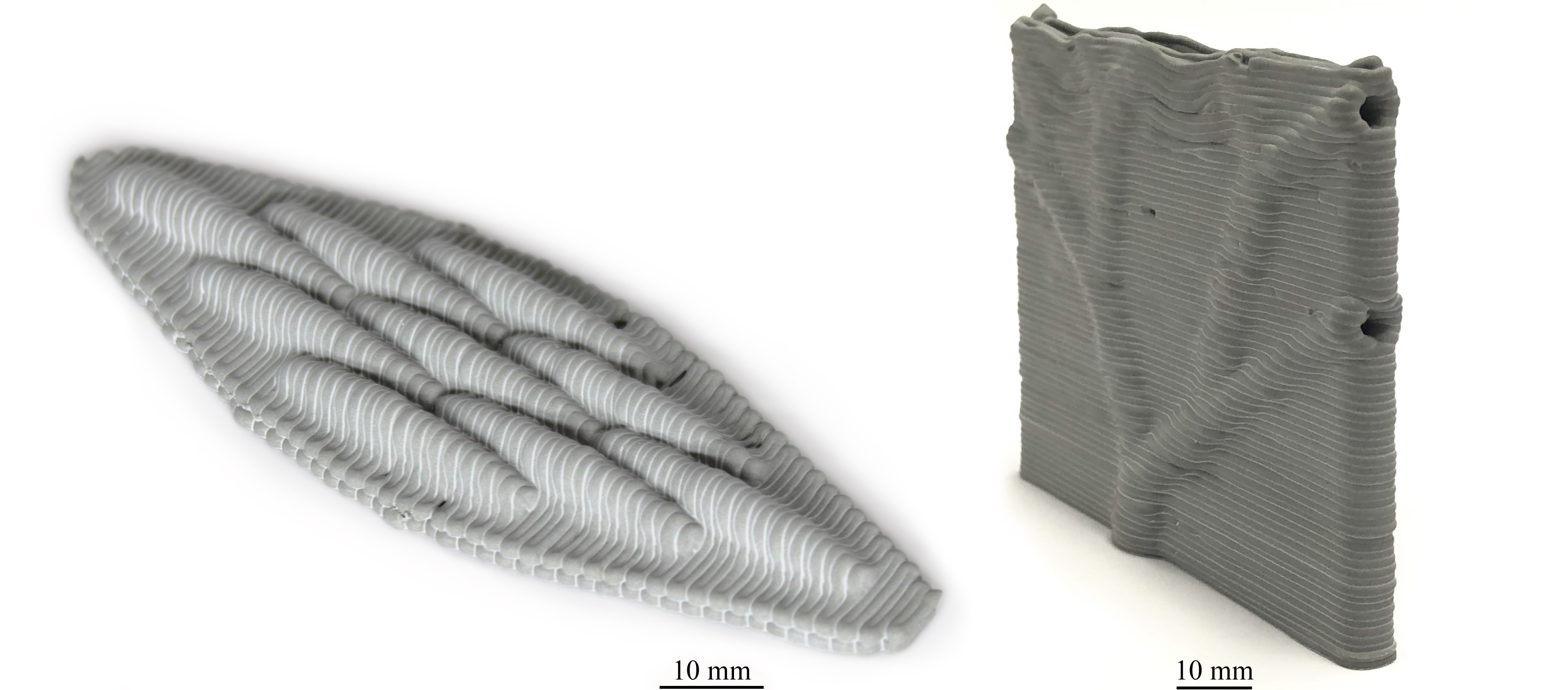

Internal cavities or channels have the potential to enhance a component's

insulation capacity, allow for fluid transport and heat exchange, and/or

reduce material use without structural disadvantages. However, extrusion-based

3D-printing of built-in cavities or channels with cement paste has

remained challenging, due to the lack of support materials. This research explored the use of angled planar toolpaths to increase the stability of the 3D-printed, mm-scale internal channels.

Our Grasshopper scripts offer several methods of rapidly generating 2D or 3D complex channel networks. The input in this automated modeling sequence is a

selection of points, from which (dichotomously) branching networks, interconnected networks, or unconnected channels can be generated.

Then, the Grasshopper scripts allow for rapid 3D-modeling of the internal channels (with the option to apply Murray's law), toolpath angle optimization for channel stability, and automated g-code generation.

Attribution

Lara Tomholt, Forrest Meggers, Reza Moini

Andlinger Center for Energy and the Environment, Princeton University

Department of Civil and Environmental Engineering, Princeton University

Publication

L. Tomholt, F. Meggers, R. Moini (2024) 3D-Printing channel networks with cement paste. In: D. Lowke, N. Freund, D. Böhler, F. Herding (eds). Fourth RILEM International Conference on Concrete and Digital Fabrication. Digital Concrete 2024. RILEM Bookseries, vol 53, pp. 74-82. Springer, Cham, Switzerland. https://doi.org/10.1007/978-3-031-70031-6_9

Grasshopper scripts: GitHub

YouTube: Grasshopper script for optimizing the toolpath angle in single 3D-printed channels

Grasshopper script for generating channel networks and optimizing the toolpath angle for 3D-printing